Fabrication

Digital Making

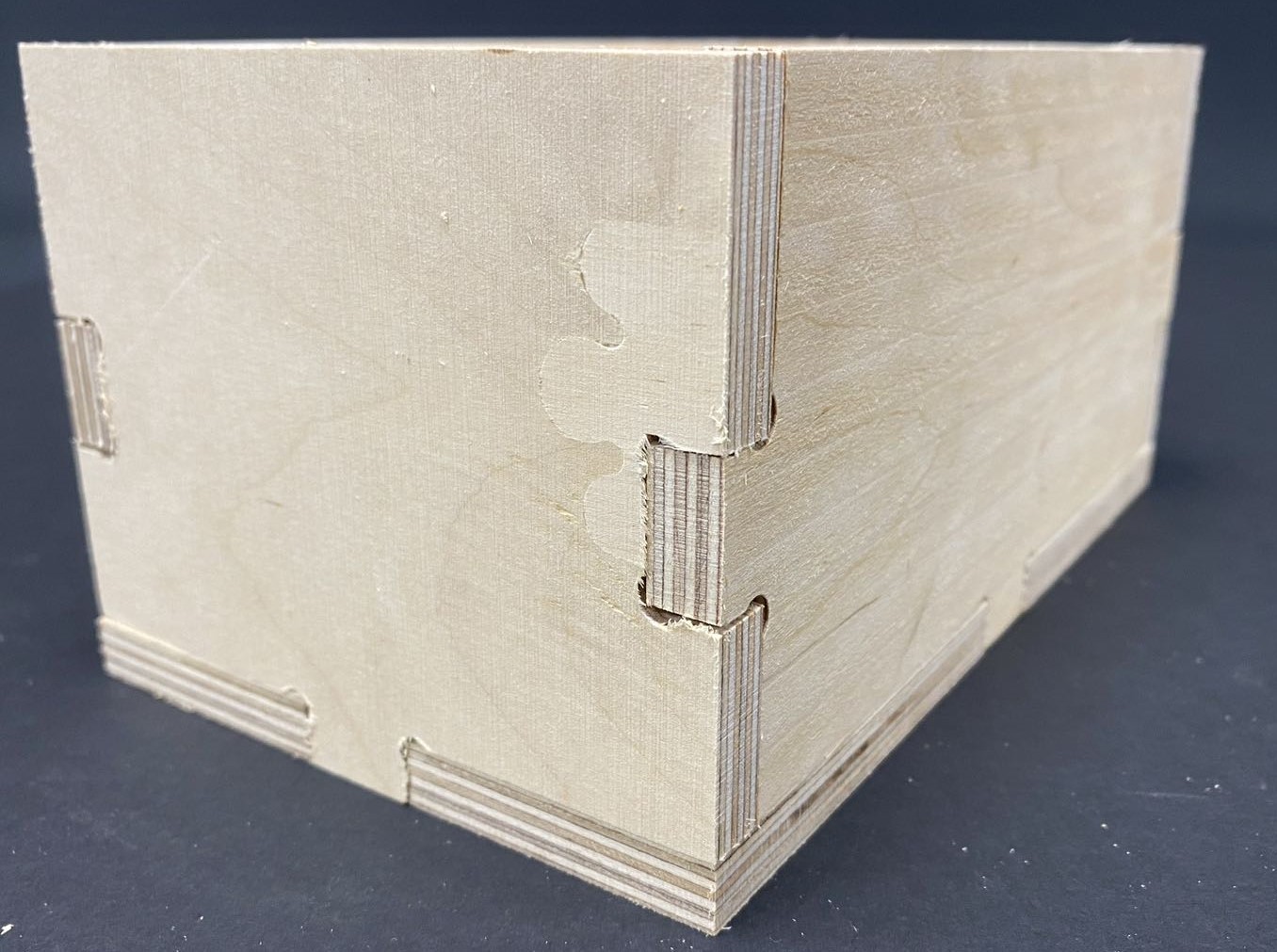

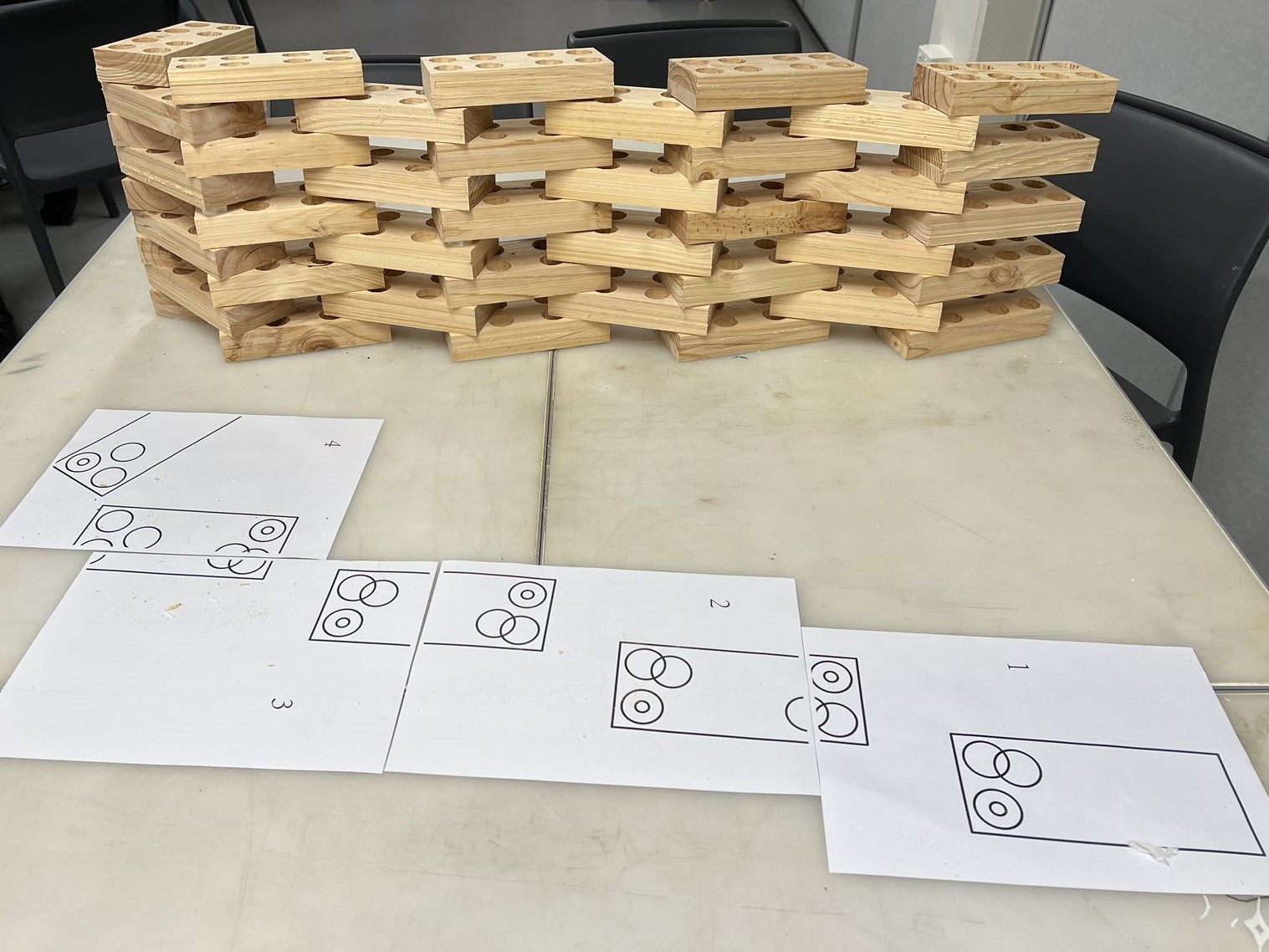

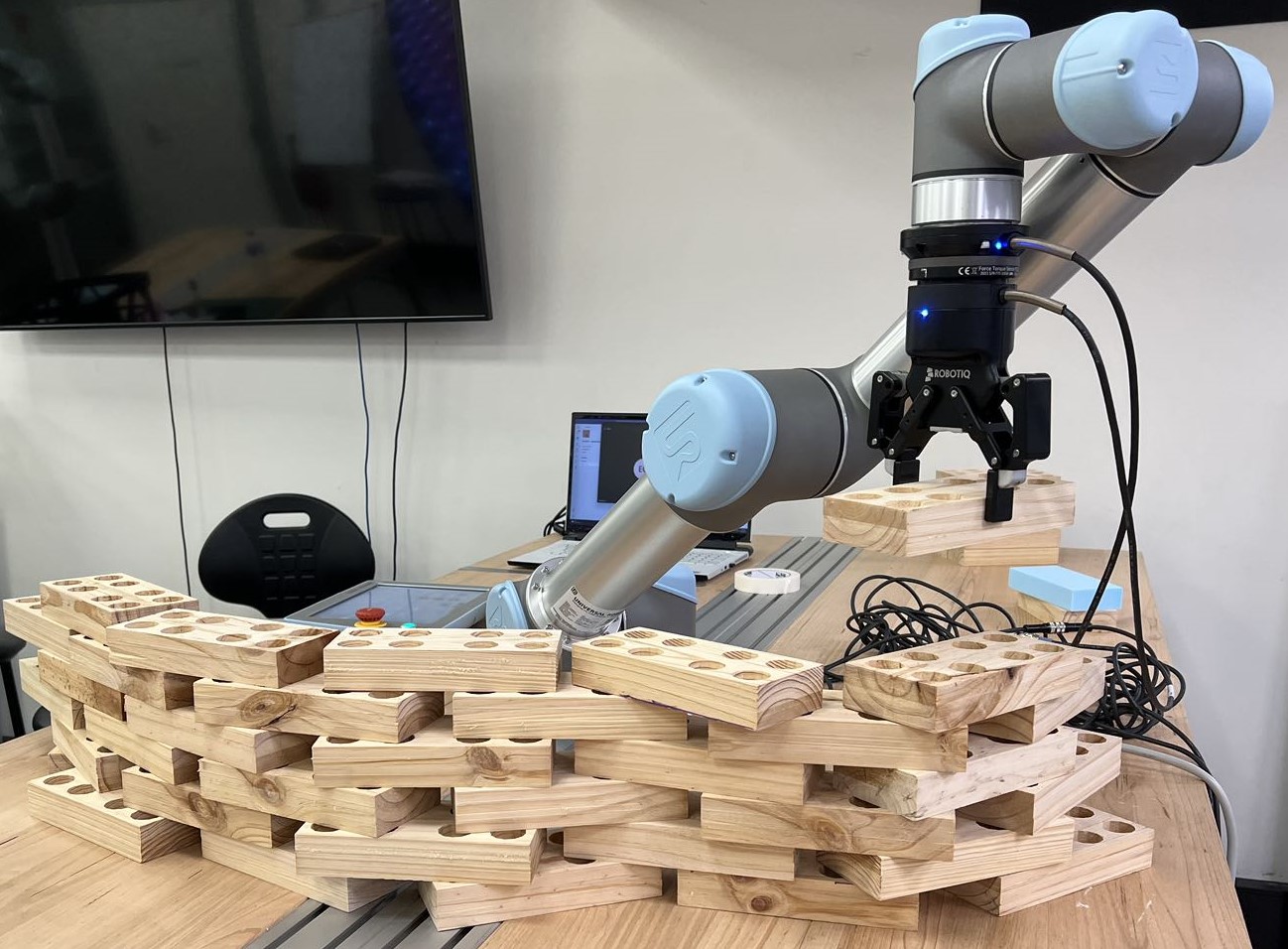

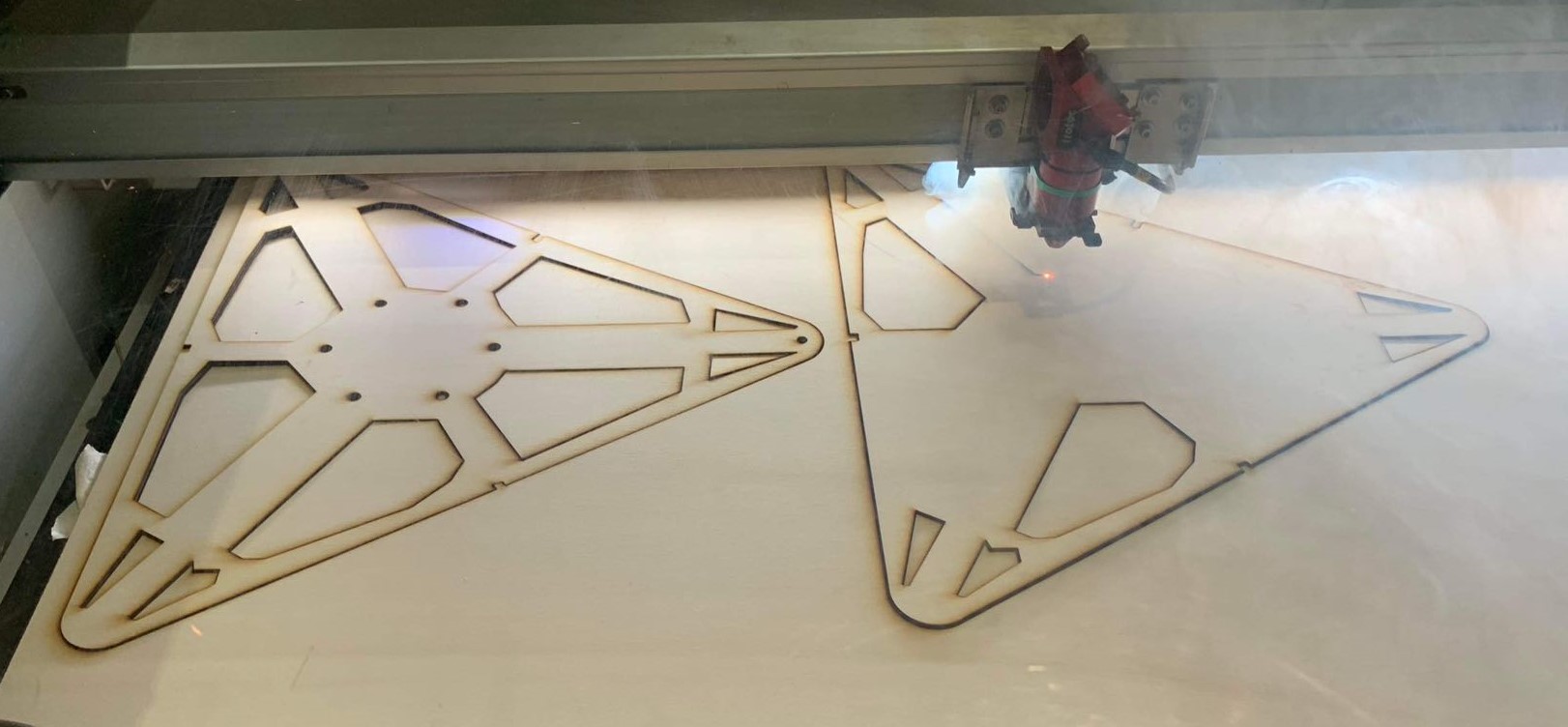

In this course I designd a complex curved feature wall for the DFL, using Rhino 3D and a provided grasshopper script.Develop tool paths and fabricate via the Tormac CNC milling aluminium molds to fabricate in a further step via plastic injection connectors.Develop tool paths and fabricate via flatbed CNC mill prototype bricks (using timber).

Acoustic panel

Design a kinetically driven acoustic panel system. The proposed panel system is to be attached to a KUKA robot arm for testing and evaluation of kinetic movement and structural optimisation. Through flexible work environments, acoustic panel systems need to respond to the contextual surroundings with different acoustic scenarios (presentation, meetings, 1on1 discussions, silent/concentrated work, etc.). The acoustic panel design will utilize soft robotics which can alter the acoustic performance of the environment – minimizing or maximizing the acoustic qualities of context. The testing scenario of the acoustic panels will be for office use. Design teams will engage a range of simulation modelling plugins (such as but not limited to: Ameba (topology optimisation), Kangaroo Physics, Karamba (structural analysis), and Pachyderm (acoustic analysis), as well as Galapagos or Octopus for evolutionary solving, to demonstrate how the acoustic panel design addresses the following primary goals: - capacity to translate the biological role model for design (biomimicry); - structural and material integrity (while static and in motion); - structural and material optimisation including attention to minimising material waste - calibration of the acoustic panels’ kinetic movement through soft robotics.